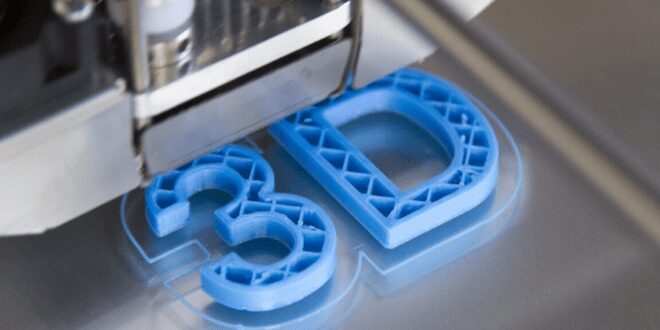

If we were living in the 1960s, 3D printing would be the stuff of science fiction. Today, the technology to print almost anything is becoming commonplace. To date, the 3D printing industry is growing rapidly with Statista.com expecting it to be worth at least $40.8 billion by 2024. What was once a figment of imagination has transformed into a rapidly growing market for solutions that are needed by other industries.

As technology continues to evolve, we will definitely discover numerous applications for 3D printing. For now, here’s what we do know about 3D printing’s relevance in our world today:

Healthcare

Perhaps the industries that could benefit most from 3D printing are medicine and healthcare. Both require more sophisticated technologies in order to provide quality care to patients and save and prolong lives. With 3D printing, healthcare institutions can provide patients with better treatment options that are less risky and, at the same time, less expensive.

For one, surgeons can take advantage of 3D printing technology in order to create drill guides that allow for improved accuracy, especially during complex procedures such as screw replacements for hip implants. Moreover, surgery areas in the human body can be 3D-printed to give surgeons a better understanding of anatomical structures better than the images provided by a CT scan.

Apart from these applications, 3D printing can also be utilized to create prosthetics and replacement parts. For one, patients who have undergone life-saving amputations can be provided by custom-fit prosthetics made from 3D printed materials. In addition, patients who suffered fractures or lost internal body parts like kidneys can opt to replace these parts through bioprinting. As healthcare institutions are beginning to invest heavily in 3D printing, we will definitely see a future in which the technology reserves a profound place in modern medical science.

Automotives

Healthcare and medicine are not the only sectors to benefit from 3D printing. In an era where factories aim to improve efficiency and reduce waste, the automotive industry has already used 3D printing for a variety of purposes, and not just for prototype development.

For one, 3D-printed cars are quickly becoming a reality, with companies like Local Motors developing a range of vehicles through what it calls as a “digital vehicle manufacturing model. This model utilizes 3D printing to develop assembly parts that are easily customizable. So far, Local Motors has completed a project called Olli, a small urban bus made entirely out of 3D-printed material. It’s a start, and it does open up a new window of opportunity for other vehicle manufacturers to follow through.

Aside from casual driving, 3D printing is also inching closer towards being widely adopted in the motorsports industry, where custom solutions are crucial towards enhancing performance at a lower cost. Through custom tooling, race teams can select printing material and reinforcing additives for 3D printed parts that give optimal results. This has not yet been adequately explored, but the idea of printing out low-cost synthetic parts that are just as sturdy as metal ones have the potential to change motorsports forever.

These benefits can also trickle down to public transportation. It will only be a matter of time before everyone gets to ride on a resin bus.

Aerospace

Of course, as a branch of transportation, aerospace manufacturing will be impacted by the widespread use of 3D printing, especially as companies like Elon Musk’s SpaceX program are banking on the possibility of commercial space travel.

It will take some time, but there have already been significant strides in the development of aerospace technology. Sure enough, 3D printing has played a vital role in the planning and production process. It’s important to know, however, that 3D printing (which went by the name of Additive Manufacturing back in the day) and the aerospace and defense industry have had a long-running history, dating back to the early 1990s.

Today, 3D printing is used primarily to test out design concepts, allowing research and development teams to make well-informed decisions in planning and creating engines that could withstand launches and outer space conditions. Moreover, 3D printing can also support the production of custom parts as well as ceramic cores which for the most part are difficult to produce, according to PERFECT 3-D.

At any rate, additive manufacturing which supported the aerospace and defense industry is a pre-existing one. Yet, with the advancement of 3D printing for more complex applications in the production of aerospace technology, the industry is expected to reach new (and literal) heights.

Education

So far, we have learned that 3D printing is mostly used along productive lines, whether it’s manufacturing synthetic limbs or creating custom molds that can reduce the cost of mass-producing unique parts in the automotive and aerospace industries. The education sector can also benefit from what 3D printing has to offer.

One instance of 3D printing as an educational aid is that it can be used for interactive classes that engage learners’ capacity for critical and creative thinking. Teachers can show digital models and let students manipulate them into certain shapes or forms which can then be printed out. Subjects such as science and technology, biology, and even astronomy can take advantage of 3D printing as a way to enrich learning experiences and prepare students for a technology-saturated workforce.

The technology is also useful in training environments. In the medical field, for instance, 3D models of body parts can be printed out for students to practice on. Engineering and architecture students, on the other hand, can use the technology to develop scale models of design and structural concepts more accurately and within a faster time frame.

Can the future get any more exciting? As 3D printing technology keeps offering us something new each year, we can only hope for more investments and innovation as industries look towards cost-effective and safer measures for building the future.

Imagup General Magazine 2024

Imagup General Magazine 2024